Science tour:

Overview about the research and laboratories

Participants on a guided tour through the test laboratories at the Environmental Campus to demonstrate sustainable technologies (@Bastian Franz).

The university provides interesting insights into a wide range of topics through its diverse departments. The collaborative interaction between these disciplines forms a diversified scientific community. The upcoming symposium will present selected laboratories and projects associated with different departments and institutes.

Robotics lab

The "environmentally compatible production processes and industrial robotics" working group specializes in the development of new control and robot applications. The demand for such technologies is currently driven by the need for energy saving strategies and raw material savings. The robotics sub-department is for basic student training in automation technology, robotics and drive technology. In addition, test benches are set up for various third-party funded projects.

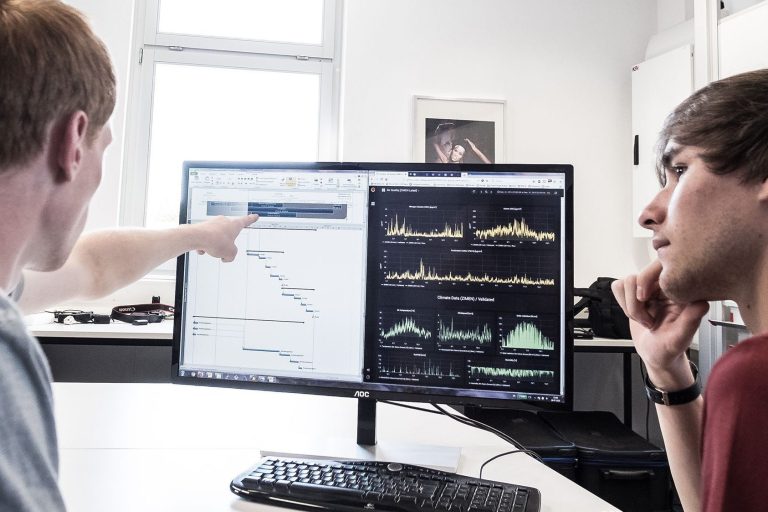

AI lab

The AI Laboratory promotes collaboration between students and regional businesses, not only in the development of mathematical constructs but also in practical testing within real-world environments. The objective is to generate innovations and establish a platform where the fundamentals of artificial intelligence are elucidated in a tangible manner, fostering the understanding of AI basics.

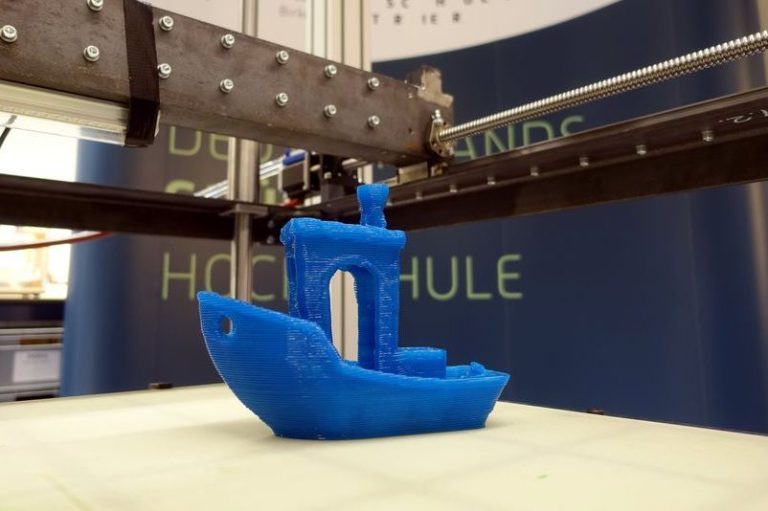

3D printing

The Additive Manufacturing Laboratory in the field of plastics encompasses various processes for 3D printing with plastics. With a pool of approximately 40 printers offering build volumes of up to one cubic meter, a variety of materials can be processed, ranging from flexible to acid-resistant. Additionally, printers are available to handle aluminum, tool steel, and stainless steel.

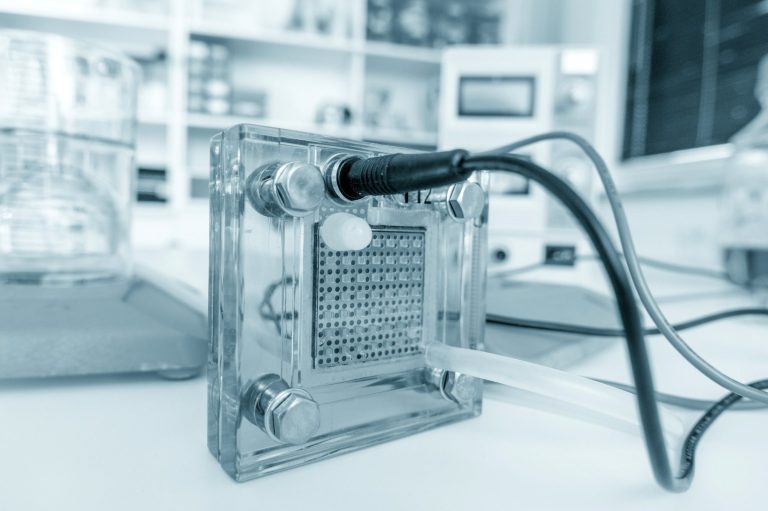

Hydrogen Lab

The battery and fuel cell laboratory is dedicated to manufacturing components for lithium-ion batteries, fuel cells, and redox flow cells, as well as conducting characterization on multiple testing platforms. Additionally, the facility is involved in the development of complete systems. As part of its infrastructure, the laboratory encompasses an electronics workshop equipped for circuit board prototyping and SMD assembly.

Battery disassembly

With the assistance of robots, high-voltage battery systems are disassembled here and prepared for reuse or recycling. The robots handle hazardous and ergonomically challenging tasks, while intelligent tools and assistance systems support humans in the remaining activities.

Reman4E-Scooter

The "Reman4E-Scooter" project is dedicated to the question of how the useful life of e-scooters can be extended. The main goal is to make the repair of e-scooters economically viable and logistically feasible, thus avoiding disposal as the last option. Led by Professor Vette-Steinkamp, his team is developing a repair container made from a recycled sea container. Inside this container, robotic stations are provided to perform critical repair work on the e-scooter in collaboration with the scooter employees.

©Copyright. All rights reserved.

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.